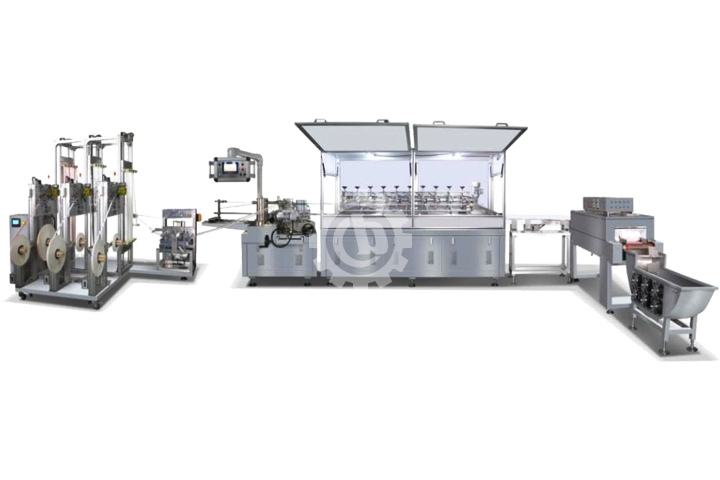

Our complete machine line transforms raw wood logs into finished BBQ sticks, ideal for disposable tableware manufacturers, food processors, and trading companies.

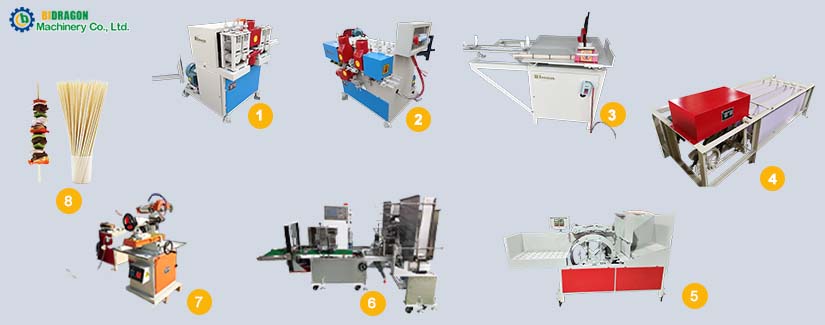

1. Wood Dissection Machine

Cuts raw logs into uniform sections for further processing, ensuring stable and efficient production.

2. Wood Wool Forming Machine

Processes thin wood slices into curled wood wool for eco-friendly packaging or crafts, with adjustable thickness and curl.

3. Precise Cutting Machine

Accurately cuts wood into consistent stick lengths for BBQ skewers, cotton swabs, or ice cream sticks, with minimal tolerance.

4. BBQ Stick Polishing Machine

Smooths stick surfaces by removing splinters, delivering a clean, food-safe finish with optional polishing powder.

5. BBQ Sticks Sharpening Machine

Sharpens one or both ends of sticks with adjustable settings for various sizes—perfect for safe, ready-to-use skewers.

6. Double Hopper Skewer Stick Packing Machine

Automates stick counting and packaging with dual hoppers, ensuring accuracy and reducing labor for retail and wholesale use.

7. Knife Sharpening Machine

Maintains sharp cutting blades across the line, extending blade life and ensuring cutting precision.