Recently, George, the head of a Russian wooden coffee stick processing company, has once again partnered with our company, purchasing an additional upgraded AI intelligent wooden coffee stick sorting machine. This repeat order not only continues the long-standing cooperation between the two parties but also demonstrates the core advantages of our equipment in terms of capacity enhancement and intelligent upgrading.

It is understood that George's processing plant introduced our sorting equipment several years ago, and its stable performance and efficient sorting capabilities have provided strong support for its production. With the growth in market demand, the plant's daily coffee stick output has increased by 30%, and the traditional equipment and manual sorting methods have gradually shown efficiency bottlenecks, unable to meet the increased production capacity demands. Upon learning that our equipment had been upgraded with AI visual recognition functionality, George immediately requested a repeat purchase.

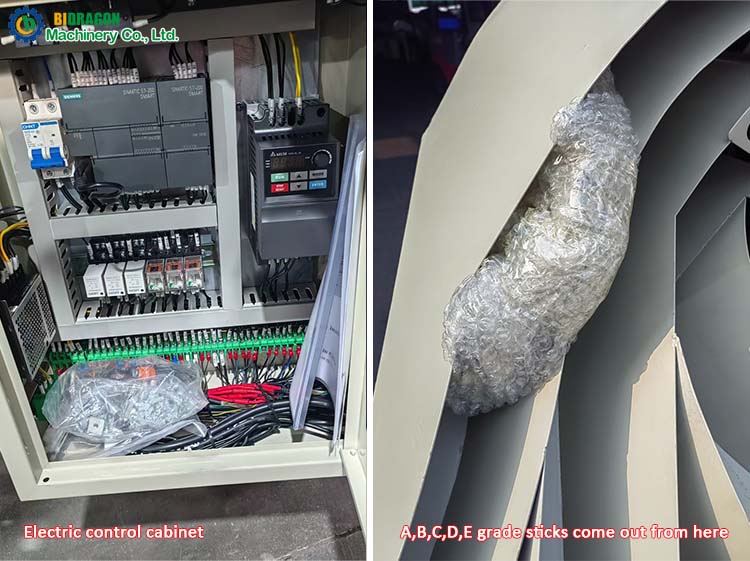

The core highlight of this upgraded AI intelligent sorting machine is its AI visual recognition system. This system can accurately identify differences in the length, diameter, color, and minor defects of coffee sticks, increasing sorting speed by 50% compared to traditional equipment, with a recognition accuracy rate of 99.8%, fully adapting to the refined sorting needs of high-capacity scenarios. To ensure seamless integration of the equipment with the customer's production line, we customized the parameters according to the contract, adjusting the sorting threshold and conveying speed to suit the coffee stick specifications.

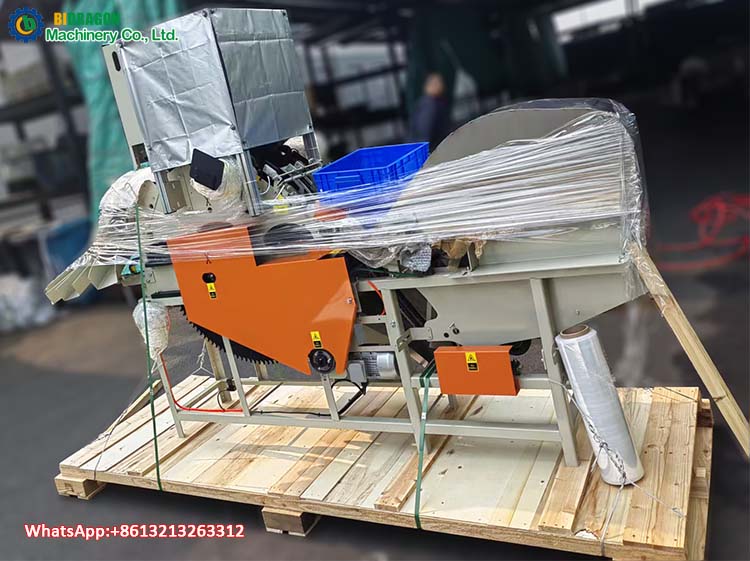

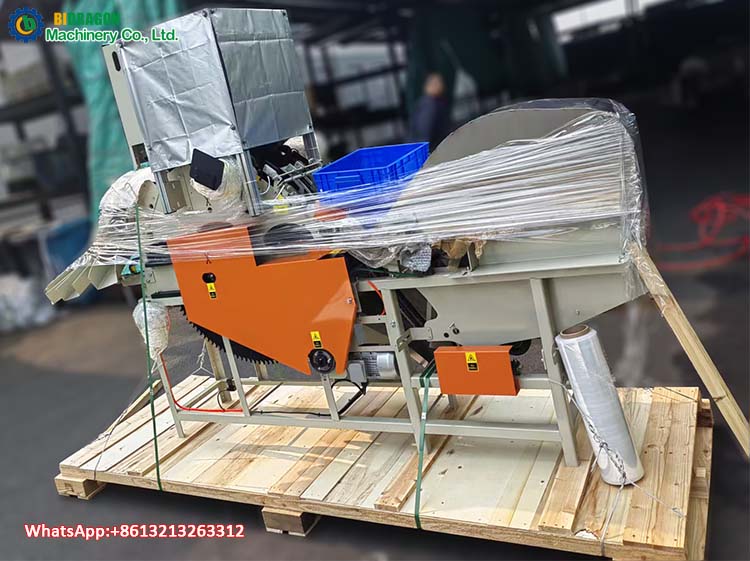

Before shipping the equipment, we conducted a trial run via online livestream, showcasing the entire process from startup and raw material delivery to finished product sorting in real time. George, who participated in the entire acceptance process, stated, "The results are even better than expected. The AI function has solved the sorting challenges under high production volumes, and we no longer have to worry about efficiency." Currently, the equipment has been shipped to Russia as planned.

From the initial collaboration to proactive repeat purchases, the customer's recognition stems from the continuous iteration of equipment technology and the stable and reliable service. In the future, we will continue to use intelligent equipment and customized services to help global wooden coffee stick processing companies improve quality and efficiency.