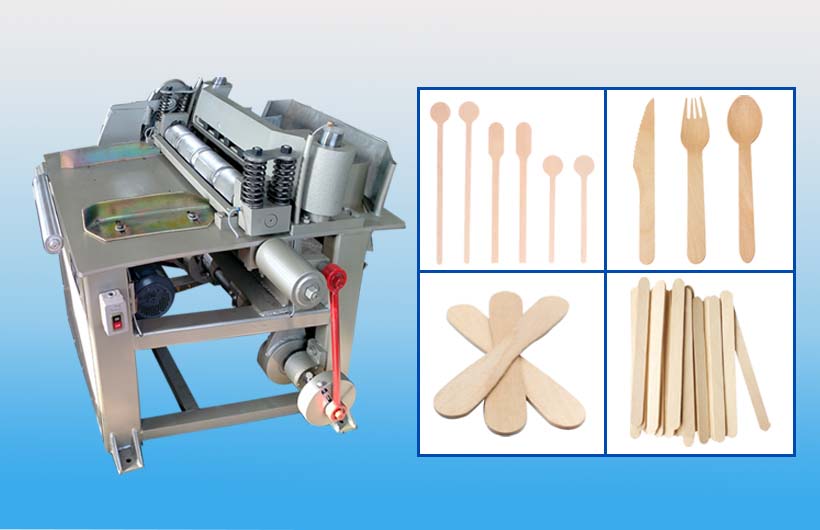

Tri-Carved Cutting Machine

Tri-carved cutting machine can cut wood veneer into different wood products ,like ice cream sticks, coffee stirrer, tongue depressor, ice spoon, wooden cutlery, etc. Just need to replace the cutter for these different final products.

Model: SLKQ-3-CNC

Process Width: 460mm

Shaft RPM: Max 500rpm/minute

Cutting Thickness: 1~20mm

Main Motor: Y series 2.2KW,1440r/min