Automatic Wire Nail Production Line

Automatic Wire Drawing Machine

This combined continuous wire drawing machine is sturdy and durable with extremely low maintenance ratio by using the canine round seal lubrication. This machine can be used as a single one or combined together.

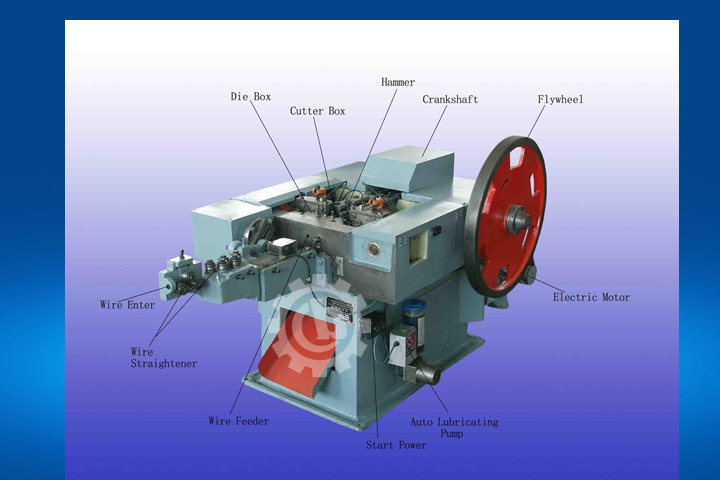

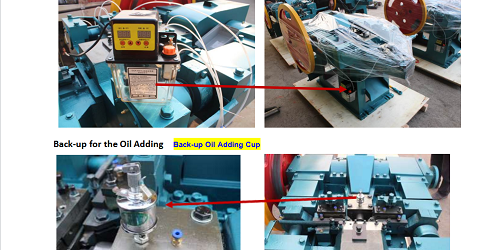

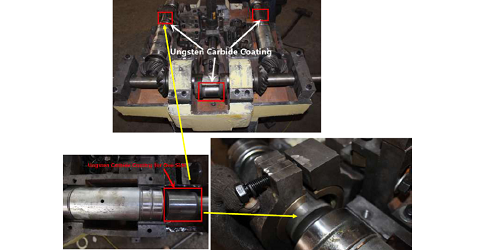

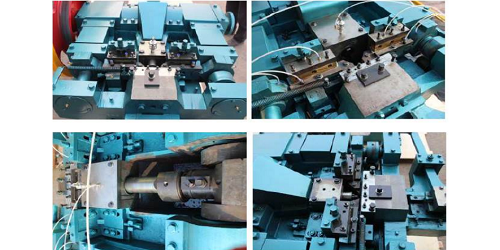

Z-94 Series Nail Making Machine

Common wire nail making machine adopts plunger type structure to ensure its high working speed, low noise and low impact characteristics. It has wide uses, simple operation, and reliable working condition. The raw material can be waste scrap or new wire rod. The nail point and the nail head can be formed at one time with a high efficiency.

Nail Polishing Machine

When the nails comes out from the nail making machine, it is not so smooth and bright, to make it bright and have a good selling appearance, it needs to be polished. Firstly put the nail in the polishing drum, then put some saw dust onto the nails,then cover it and start the machine, in general it needs 2 hours’ polishing.

Accessory Equipment for Nail Making Line

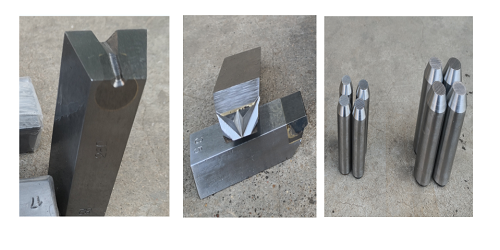

1. Knife Grinding Machine

Because after 1-2 days cutting,the nail knife installed on the wire nail making machines will become blunt,then you can use the nail knife grinder to grind the nail knife to make it sharp again.

2. Butt Welding Machine

In case the wire breaks during drawing,you can use the butt welding machine to weld the broken wire together ,then continue the drawing.without this machine,if the wire breaks,you need to sharpen the wire head again and do all things from the start.

3. Nail Pointing Machine