Today’s technology offers many different nail making machine designs available for purchase by the manufacturing and the building industry. These machines are produced overseas by a wide variety of companies in countries like India, China and USA. The different available machines are designed for production of different nail designs. E.g. there are different machines for producing box nails, screw nails, finishing nails, cut flooring etc. and different machines for different inches of nails. The first step to evaluating nail making machine design was to find out what products were currently available in the industry.

1.Our Perfect Automatic Wire Nail making machine

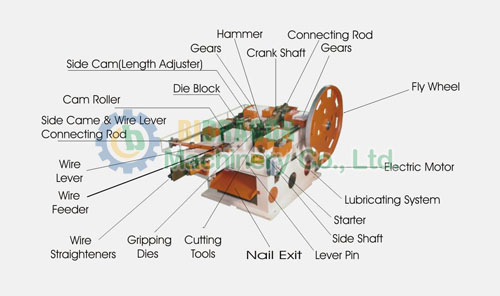

It is simple and sturdy in design and is made from high grade casting & steel. There is a range of them which can produce flat head nails, pop nails, round head nails, lost head nails, counter sunk head nails, from copper, aluminium & brass Wires. Its main crank is directly driven by motor and side-shafts are driven by four bevel gears to ensure correct and permanent adjustment of the cutting tool. The length and thickness of the nails is adjustable. All tools are easily accessible and can be quickly changed. Its main and side shafts are fitted with bushes to ensure long life. All cams, gears, rollers, roller pins are made from high-quality steel properly heat-treated and grounded for long lasting.

2.N6-E Nail Making Machine

This nail making machine was manufactured in USA. In this case, the wire form wire coil passes through straightening rolls and fed intermittently into the gripping dies which close firmly head of the nail. The grip is loosened now and the required length of wire is fed forward. Then the cutting tools cut the point a little forward of the grip leaving sufficient wire projecting to form the head of the next nail. This sequence of operations is repeated at each revolution of the machines and the nails are produced constantly. The frame of the machine is rigid; all moving parts are of ample dimensions and precisely made from quality material which ensures the smooth running of machine in spite of high rate of output. The wire feed is actuated by means of gears mounted on one side shaft which moves the feed slide through connecting rod. The bush bearings are made from special metals and provided with continuous approach of oil which ensures the smooth running and long life.